Copyright © Dongguan EMHEATER Electrical Equipment Co., Ltd. All Rights Reserved. Site Map

The main features of inverter for constant pressure water supply system:

● When the demand of the water supply changed, the outlet pressure keep sun changed, and the output pressure value is according to the user’s demand.

● It can save 10%~40% electricity and achieve green electricity use.

● It can be automatic, save manpower and resources, low cost and high efficiency.

● Due to the frequency inverter ‘stable speed control, the water supply from the headwaters, compared with the water supply before, it will reduce the second pollution.

● Reasonable operation, soft start and soft stop can not only eliminate water hammer effect,but reduce the average torque and abrasion of the motor, the repair times and cost, and increase the working life of water pump.

The main applications of inverter for constant pressure water supply:

● Domestic water of high buildings, urban and rural residential quarter, company and etc.

● All kinds of industrial use water, cooling water circulation, the boiler filling water and etc.

● Central air-conditioning system.

● Water plant pressurization system.

● Farm irrigation, water treatment, and fountain.

● All kinds of fluid constant pressure systems.

System debugging:

● Debugging mainly includes the following technical points:

● Make sure the feedback source and realize closed-loop PID control.

● Adjust the PID parameter value, so that the pipe network pressure is stable. The fluctuation is small.

● Input the basic inverter parameters, frequency setting mode, acceleration and deceleration time, etc.

● Input feedback signal source 0-10v, 4-20mA, observe its range by parameters, and calibrate the parameters by group C0/C3.

Inverter display interface description:

After setting the parameters, the keypad upper line shows the feedback pressure by default, which can be automatically restored to the frequency interface by adjusting the upper and lower buttons.(as the following pictures)

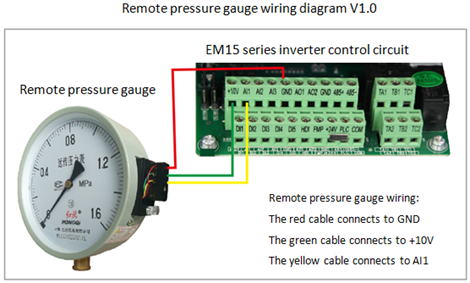

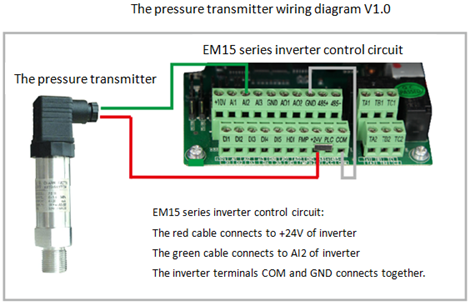

Wiring diagramreference:

Parameter setting sheet:(Generally use following parameters)

Function code Function description Default Setting value Remark b0-02 Command source selection 0 0 0.board control 1.external terminal control b0-03 Main frequency resource selection 1 8 PID control C0-00 PID setting source 0 7 C3 group pressure control C0-03 PID feedback source 0 The remote pressure gauge set to 0,the pressure transmitter set to 1. C3-00 Target pressure setting 0.200 Adjust according to the applications Unit:MPa C3-01 the maximum value of feedback pressure 1.000 C3-03 The protect pressure of explosion-proof pipe 1.500 C3-04 Wakeup pressure 80.0% Eg:Target pressure is 0.5MPa,wakeup pressure is 0.5MPa*80%=0.4MPa. C3-07 Sleeping frequency 20.00HZ This value setting set to 1 or 2HZ more than the value there is no one to open faucet of water pipe.

If it don’t need sleeping mode, please set C3-04 =100,C3-07=0.

The application parameters optimization:(the following parameters setting is according to the application demand,don’t set if there is no special demand.)

b0-21 | Acceleration time | 0-650s | It will be benefit to the system performance if set suitable acceleration and deceleration time |

b0-22 | Deceleration time | 0-650s | |

C0-06 | The proportional gain Kp1 | 20.0 | The value larger, the adjustment stronger |

C0-07 | The Integral time Ti1 | 0.8 | The value smaller, the adjustment faster |

C0-16 | PID initial | 0.0 | Fixed PID value output at startup |

C0-17 | PID initial holding time | 0.00s | Fixed output frequency holding time at startup |

C0-25 | Detection value of PID feedback loss | 0.0% | These parameters are used to judge whether the PID feedback is lost. If the PID feedback is smaller than the value of C0-25, and the lasting time is exceeds the value of C0-26, the inverter will report Err31.(The default setting is 0.0s) |

C0-26 | Detection time of PID feedback loss | 0.0s |

The larger C0-06 value, the system is more sensitive and the reaction will be faster. But the system reaction need some time, so too bigger value will cause system over adjustment and vibration.

The smaller C0-07 value, the reaction of system will be faster. But the system reaction need some time, so too smaller value will cause system over adjustment and vibration.

SettingC0-23, C0-24 value too big, that will causes slowly system reaction.